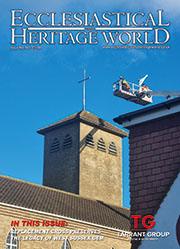

New roof restores brutalist masterpiece – and rectifies design flaw

A major roofing and cladding project – using traditional mastic asphalt and leadwork – was carried out over the whole of last year at St Antony’s College, Oxford, by leading industry experts SPV Group. The project, at the Hilda Besse Building, was completed as part of a larger scale refurbishment project – working in conjunction with CBRE Construction.

A major roofing and cladding project – using traditional mastic asphalt and leadwork – was carried out over the whole of last year at St Antony’s College, Oxford, by leading industry experts SPV Group. The project, at the Hilda Besse Building, was completed as part of a larger scale refurbishment project – working in conjunction with CBRE Construction.

Completed in 1970 by John Partridge, the Hilda Besse Building sits at the heart of the college and houses many of the college’s key social spaces, including the dining hall, common rooms and buttery, as well as private dining facilities and kitchen. It is a Grade Two-listed building and is said to be one of the finest examples of post-war brutalist architecture. The building won the RIBA Architecture Award and Concrete Society Award in 1971 – noted for its skilful application of concrete in a modern interpretation of a traditional hall.

In 2019 a wholesale refurbishment of the building was commissioned by the college trust. The works were important both for the safety and longevity of the building itself and to improve its ability to serve the college community. Overall, it is estimated that the total refurbishment will cost in excess of £9m once fully complete.

SPV Group assisted CBRE in the renovation of the mastic asphalt roof and the bespoke lead panelling that is duplicated on all elevations of the building. Part of SPV’s remit was to strip the existing asphalt roof, which was at the end of its useful life.

SPV Group assisted CBRE in the renovation of the mastic asphalt roof and the bespoke lead panelling that is duplicated on all elevations of the building. Part of SPV’s remit was to strip the existing asphalt roof, which was at the end of its useful life.

The existing plywood deck was also defective and required replacement, with SPV supplying and installing a new vapour barrier, thermal insulation and mastic asphalt, creating a warm roof construction.

The main challenge regarding the project was that all 88 rooflights had to be individually altered to accommodate the new roof design.

A timber frame was created around each rooflight to incorporate a self-adhesive bitumen vapour barrier, followed by 110mm insulation. Every part of the timber frames needed to be prepared with a sheathing felt, followed by expanding metal lath to receive the correct application of the mastic asphalt. The installation was carried out according to the recommendations of the Mastic Asphalt Council, the industry body for the correct installation of the material, in order to provide manufacturers’ warranties for the installation.

Once prepared, three coats of roofing-grade mastic asphalt were applied to all of the upstands, with two 10 mm coats on all flat areas. That was followed by a two-coat asphalt fillet finish, which joined the upstands to the flat area using a warm and clean method – ensuring a solid seal.

Once prepared, three coats of roofing-grade mastic asphalt were applied to all of the upstands, with two 10 mm coats on all flat areas. That was followed by a two-coat asphalt fillet finish, which joined the upstands to the flat area using a warm and clean method – ensuring a solid seal.

The whole roof was then completed with two coats of solar reflective paint in heritage grey colour.

Only half the roof was under a protective temporary scaffold roof, adding pressure to delivery. SPV needed to ensure that the exposed half was sealed at all of the stages outlined as internal ceilings were being finished underneath by other contractors.

Due to the nature, shape and size of the building, the gutters were laid to falls using the asphalt.

SPV worked closely with the Mastic Asphalt Council and material manufacturer IKO throughout the works, with regular technical and QA inspections being undertaken throughout the project, to ensure that quality standards were met – taking into account the difficult nature of the project.

In order to maintain and replicate the appearance of the original façade, and to ensure no issues with Planning Permission arose, replacement lead was specified once again as the primary material.

In order to maintain and replicate the appearance of the original façade, and to ensure no issues with Planning Permission arose, replacement lead was specified once again as the primary material.

In addition to the façade panels, bespoke lead box gutters with built-in outlets were installed, with those in the façade of the plant room walls at a higher level. The bespoke lead panels were sized from the original panels to ensure that fitment was not an issue.

The original lead panels were severely weathered, leading to a poor appearance not in keeping with such a remarkable building. SPV Group’s experienced leadworking team created the new panels on site and finished them with a prefabricated lead dome to create the previous ‘button’ feature, which doubled up as a form of concealment for the mechanical fixings.

The new lead box gutters were also created on site to line the detail up within the façade drainage make up. When originally installed in the 1940s the downpipe that connected to the bottom of the box gutter protruded through the lead wall façade panel and was moulded from lead. The original design had an inherent design flaw which caused blockages due to leaves and debris falling and silt forming in the gutter. While maintenance teams had attempted to unblock the pipe, it subsequently caused damage to the lead lining and in extreme cases ruptured the lead welds.

The new lead box gutters were also created on site to line the detail up within the façade drainage make up. When originally installed in the 1940s the downpipe that connected to the bottom of the box gutter protruded through the lead wall façade panel and was moulded from lead. The original design had an inherent design flaw which caused blockages due to leaves and debris falling and silt forming in the gutter. While maintenance teams had attempted to unblock the pipe, it subsequently caused damage to the lead lining and in extreme cases ruptured the lead welds.

To combat that problem SPV carried out a series of welds as a future proofing measure. They welded copper flutes to stainless steel flexible pipe, then welded lead flutes to the copper flutes and finally welded the lead flutes to the lead box gutter and the outlets.

The external plant room walls were entirely clad with lead, which required replacing. That posed significant issues, as the leadwork previously fitted was to a lower standard. The renewal of those lead panels had to adhere to the latest LSTA guidelines.

SPV declared themselves ‘incredibly proud to have delivered this extremely challenging and interesting project’.

For further information visit www.spv-uk.co.uk