One cog in a very big machine

The construction of a ‘silver sundial’ in the Olympic Park has been a tiny cog in the huge machine that has been working away since 2008 to build the Olympic venues and surrounding facilities in east London. The project has demonstrated in miniature the kind of co-operation between different companies – offering different skills, expertise and experience – that has characterised the way the enterprise as a whole has developed.

The construction of a ‘silver sundial’ in the Olympic Park has been a tiny cog in the huge machine that has been working away since 2008 to build the Olympic venues and surrounding facilities in east London. The project has demonstrated in miniature the kind of co-operation between different companies – offering different skills, expertise and experience – that has characterised the way the enterprise as a whole has developed.

The sundial came about as a result of a competition launched by the Royal Horticultural Society in 2009 to design parts of a ‘Great British Garden’ in the park.

The winners were amateur garden enthusiast Rachel Reid and 12-year-old Hannah Clegg, who won the opportunity to work with the professional garden designer Sarah Price. The garden comprises ‘gold’, ‘silver’ and ‘bronze’ sectors and Hannah’s sundial is incorporated into the ‘silver’ sector. The overall design for the parkland was by LDA Design and US landscape specialists Hargreaves Associates. David Brown Sundials of Somerton, Somerset, was appointed as sundial specialist and supplier of the components for the project. The professional team on the site also included Arup Landscape, Skanska and Willerby Landscapes.

The overall design for the parkland was by LDA Design and US landscape specialists Hargreaves Associates. David Brown Sundials of Somerton, Somerset, was appointed as sundial specialist and supplier of the components for the project. The professional team on the site also included Arup Landscape, Skanska and Willerby Landscapes.

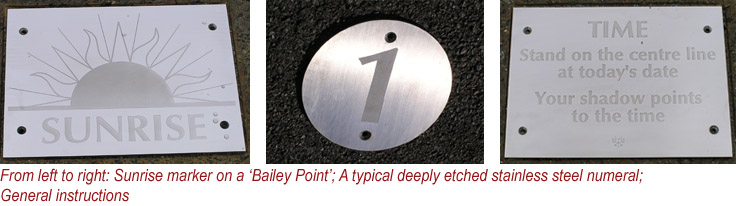

The design is for what is known as an ‘analemmatic’ sundial, which is built flat on the ground, with two sets of hour points laid out around an ellipse (one for GMT and one for BST). The user stands on a date scale in the centre of the dial, which shows the correct place to stand throughout the year. Additional markers explain how to use the sundial, also where and at what time the sun rises and sets. As this was to be a ‘silver sundial’, in the ‘silver’ sector of the garden, it was decided that the hour points and instruction plates should be made of stainless steel.

This sundial – like all others – had to be designed for the latitude and longitude of the site and orientated correctly. In this case, and almost uniquely, the Prime Meridian (0 degrees) passes almost directly through the Olympic Park, originating as it does at the Royal Observatory, Greenwich, about four miles to the south. Nevertheless, a true north/south line is needed at the site for getting the orientation of the dial correct.

David Brown visited the Olympic Park in June last year to establish that north/south line and lay out the correct positions for all the components, working with the team from Willerby’s. An interesting divergence of readings emerged between the high-tech ‘satnav’ method of the Skanska surveyors and David’s low-tech method using a board, set square, pencil and the shadow cast by the sun. The discrepancy would have meant a difference in time of 15 minutes on the finished dial. Following an amicable discussion it was decided to go with the sun reading – after all it was to be a sundial!

David also took azimuth readings on site to ensure there would be a clear path through the trees and over the stadium for the sun to shine on the dial. Meanwhile the components were sourced, manufactured and delivered from all over the country. The central date scale of the dial was made from a fine piece of monumental-quality Welsh blue-black slate, which was transported to Knutsford in Cheshire to have the stainless steel for the markings bonded into it. At the other end of the country, stainless-steel discs and rectangles were being cut in Lyme Regis in Dorset. In David’s home town of Somerton, local engineering company Fisher’s was precision drilling the countersinks in the dial for them to be installed.

Meanwhile the components were sourced, manufactured and delivered from all over the country. The central date scale of the dial was made from a fine piece of monumental-quality Welsh blue-black slate, which was transported to Knutsford in Cheshire to have the stainless steel for the markings bonded into it. At the other end of the country, stainless-steel discs and rectangles were being cut in Lyme Regis in Dorset. In David’s home town of Somerton, local engineering company Fisher’s was precision drilling the countersinks in the dial for them to be installed.

Installation of the sundial was completed in January. It will come alive during the games and afterwards, when visitors to the Great British Garden will pass through the gold, silver and bronze ‘rings’ and experience the colour, fun and discovery which was built into the original vision and realised through the contribution of just some of the vast number of contractors who took part in this great endeavour.

• For more information on David Brown Sundials visit www.davidbrownsundials.com.