Roofers learn the ropes to repair Manchester’s Jewel

The elevations and roofs of the Town Hall Extension are well known iconic land marks for anyone in Manchester and are an imposing sight – the 20 metre-high roofs having in the region of 400 tonnes of sand-cast lead sheet installed on them.

The elevations and roofs of the Town Hall Extension are well known iconic land marks for anyone in Manchester and are an imposing sight – the 20 metre-high roofs having in the region of 400 tonnes of sand-cast lead sheet installed on them.

J Hempstock & Co Ltd became involved in the project in November 2010 when the interviewing process began with the client, architect, English Heritage and principal contractor. Initial design ideas for access strategies were offered, which was considered the most difficult aspect of the work.

It was something that Hempstock’s were keen to be involved in, as three generations of the family have worked on the buildings and roofs and it has been always their ambition to be involved in their major overhaul.

The brief for the roof restoration was originally to replace a large quantity of failed Code 8 sand-cast lead panels with new ones, installed to the same detail as the originals, while ensuring that they conformed to the latest Lead Sheet Association recommendations.

The lead sheet removed for reinstallation was lowered to the ground and delivered to the sand cast manufacturing company to be re-cast into the new panels.

The lead sheet removed for reinstallation was lowered to the ground and delivered to the sand cast manufacturing company to be re-cast into the new panels.

Many hundreds of repairs to splits and failures in the material have caused in part what the technical specification tells us are incorrect details.

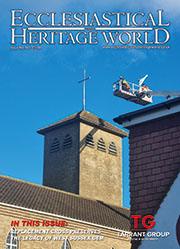

Working on the main roof slopes had its own issues. The roof having in the region of a 60o slope, scaffolding could not be installed and the only access was via large, relatively mobile platforms suspended on steel ropes with all operatives securely harnessed by independent ropes and supervised at all times by fully-trained climbing supervisors.

To enable them to carry out the work, all those involved on the project and likely to be working on the roofs – including those who were to carry out inspections and surveys – were required to attend a full week course at ‘Leeds Wall’, where they underwent five days of strict training in the safe use of harnesses, rigging and rescue.

Said Mike Hempstock: “Generally we found those people who do this sort of thing for a hobby or for their full-time jobs are light, fit and agile – for those of us who are used to installing lead sheet with feet firmly on scaffold, or those who are used to working behind a desk, the rope access course presented its own challenges, not least climbing 40 feet in the air across beams with nothing but ropes and straps to cross open spaces, and abseiling down over obstacles.”

It has to be said that not all passed – some found the challenge too great on their bodies and some found phobias which had never previously presented themselves. Some required more than one week’s training.

Mike continued: “It was not an option for me to fail, despite being informed that I was the oldest person to try for the course that year. Great encouragement!

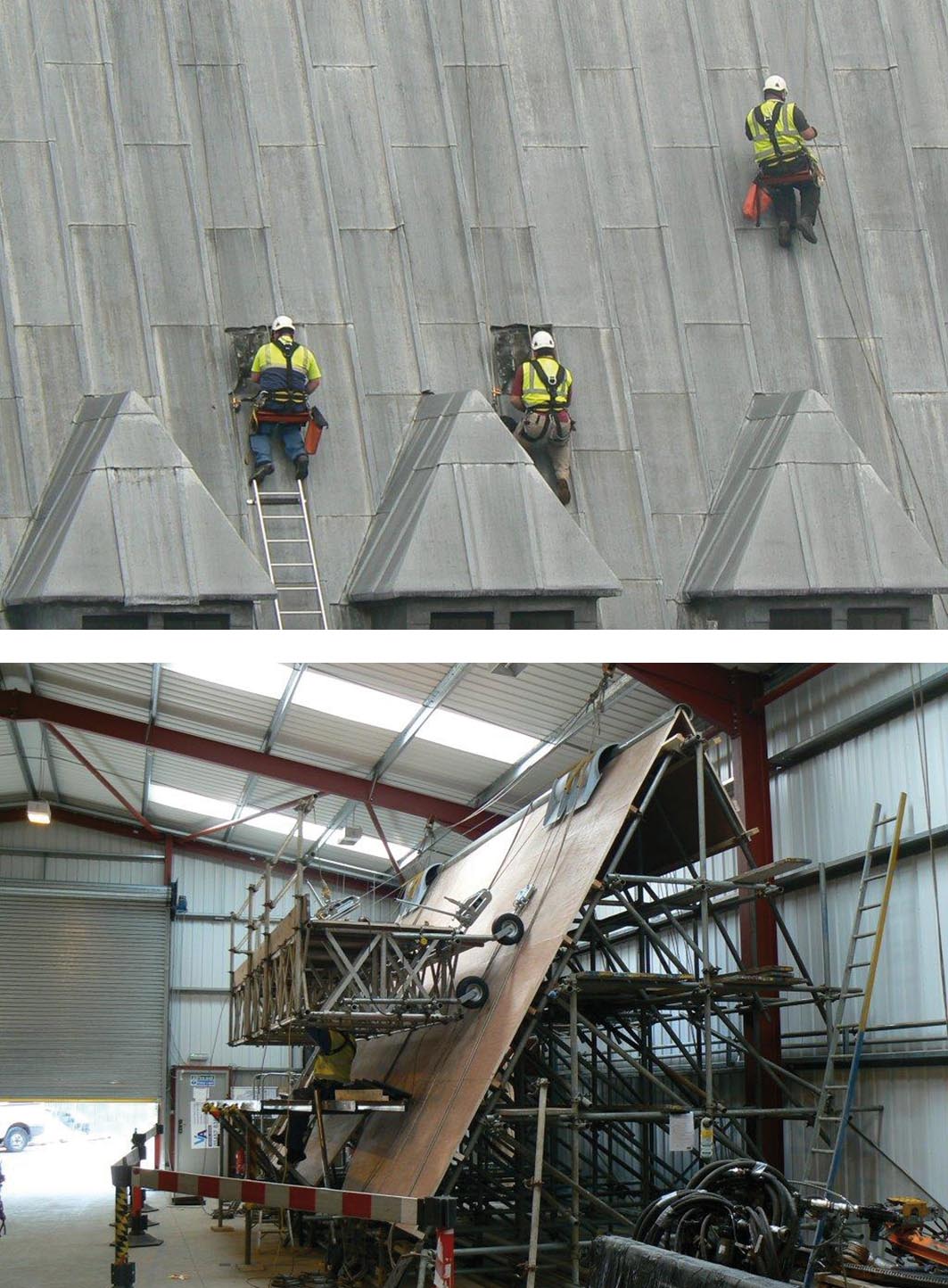

“Finally after the courses were completed and the guys chosen for the various works, we were tasked with providing a full-size mock-up of a section of the Town Hall Extension roof on which we were to practice our theories and discover what installing an 80kg piece of lead was like while harnessed and suspended 100ft in the air.”

“Finally after the courses were completed and the guys chosen for the various works, we were tasked with providing a full-size mock-up of a section of the Town Hall Extension roof on which we were to practice our theories and discover what installing an 80kg piece of lead was like while harnessed and suspended 100ft in the air.”

After several days of installing, removing and repairing sections of the Code 8 sand-cast lead sheet and getting used to working from harnesses the enormity of the task became apparent – wherein they could be potentially required to remove and replace over 2,000 lead panels.

After the filming of the tasks to be carried out on the ‘mock up’ for use in the method statement and the final design issues being agreed, the platforms could be manufactured to await transportation to the site. They were craned into position using some of the largest cranes available. Purpose-built equipment was manufactured to enable the platforms to be suspended and moved vertically and horizontally as works progressed. To enable the rigging to be installed and in order to take the weight of the largest platform – which was in the region of 3 tonnes when fully laden – tests for anchor points were carried out on various positions within the perimeter gutters and at low-level positions around the perimeter of the roof.

Mike Hempstock takes up the story: “It was soon apparent that the structure at the base of the gutters was not suitable to support the cradle weights. We had one option left: the removal of sections of lead sheet around the perimeter of the roof, exposing the boards which were cut away as well as the ‘fondant cement’ and terracotta tiling formed as substrate.”

The roof was cut out at positions around the perimeter to expose the existing steel structure. Tests were carried out and it was confirmed that they would be suitable for the installation of the anchor points. Purpose-made brackets were fitted for the rigging team to install enough ropes to suspend not only 10 operatives but three platforms weighing 2-3 tonnes each.

After a period of organisation lasting approximately 4 months the platforms were hoisted into position and rigged ready for commencing on site. Positions for placing them were restricted and after their initial lift several operatives spent days relocating the platforms before any leadwork could start.

After a period of organisation lasting approximately 4 months the platforms were hoisted into position and rigged ready for commencing on site. Positions for placing them were restricted and after their initial lift several operatives spent days relocating the platforms before any leadwork could start.

Once work started it soon became apparent that the surveyed works bore little resemblance to the actual requirements on site so the roofs were inspected in sections and failures recorded, while the team awaited instruction on how to proceed.

The leadwork was in very poor condition and there were many failures on most of the panels. The original plan of repair and replacement became a repair only as over 1,200 additional failures were identified on the southern elevation alone.

The panels had originally been installed using a single row of cut copper tacks approximately 1-2 inches long. These had either cut through the lead sheet or fallen out as the panels expanded. The panels were installed with a 3-inch welt running vertically, complete with 4-inch copper clips inside the welts which were twisted and cutting into the lead sheet, causing buckling and scoring, and restricting expansion of the lower sections of the lead panels.

The south-facing elevations of the roofs were de-seamed, repaired, repositioned and re-fixed using three rows of copper ring shank nails. Existing copper clips within welts were replaced or reformed and re-installed. Rebates were installed to the under-cloaks ensuring that future expansion can occur. That operation was carried out to approximately 3,000 panels, along with a few hundred new panels where repair was not an option. The works in those areas lasted 18 months and involved eight operatives trained to IRATA level 1 and three specialist IRATA 3 supervisors.

Once the panels on the elevations were made secure and installed correctly the ridge could be tackled. This had been installed by using the upper row of lead bays bossed over the top of the ridge and was neither nailed nor clipped. It had slipped and failed at that point.

Mike Hempstock explained: “The ridge was redesigned and installed in separate Code 8 panels, ensuring adequate cover was given to the panels below, with their three new rows of nails. We then manufactured small individual sections to enable previous welt positions to remain, so that the silhouette of the ridge did not alter from the original. The original lightning conductor was fitted to the new ridge with welded lead clips.”

Mike Hempstock explained: “The ridge was redesigned and installed in separate Code 8 panels, ensuring adequate cover was given to the panels below, with their three new rows of nails. We then manufactured small individual sections to enable previous welt positions to remain, so that the silhouette of the ridge did not alter from the original. The original lightning conductor was fitted to the new ridge with welded lead clips.”

The ridge being 150ft from the ground, the work was again carried out by rope access – but now with ladders as the platforms could not be raised to that position.

While the works to the roof were on-going, the replacement of 57 Code 6 sand-cast lead dormers had already begun.

There are 72 dormers on the Town Hall Extension building, with 57 on the more southerly elevations exposed, having suffered badly from cracking. Remedial works over the years had seen fixes installed to ensure the panels didn’t lift or fall away, but that had exacerbated the situation and failures continued to occur. The vertical cheeks and faces of the dormers can be seen to be black, while the sloping roofs were grey. It was thought by the contractor that a paint type product had been applied to the lead sheet but samples indicated it was many years of pollution.

Following removal of the bronze windows, the new installation was to be carried out using Code 6 sand-cast lead sheet to the latest specifications, with several sample installations being provided for the client, architect and English Heritage before agreement was reached on how the dormers should look.

While operatives from J Hempstock & Co continued with the roofs and dormers on the Town Hall Extension, work began to inspect, repair and renew Code 8 panels at the Central Library.

While operatives from J Hempstock & Co continued with the roofs and dormers on the Town Hall Extension, work began to inspect, repair and renew Code 8 panels at the Central Library.

The library was emptied of books and significant structural restoration and refurbishment began in 2011.

J Hempstock & Co were instructed to carry out the roof repairs and renewals on the lead domes – both inner and outer – along with complete replacement of cast-iron rainwater goods, again by the use of rope access and internal hoists.

The roofs again showed significantly more failures on close inspection than the original survey had indicated. Those additional issues were the cause of many meetings and discussions and it was clear from an early stage that the original quantities were woefully inadequate. A decision was made that no additonal repairs were to be carried out to those in the original survey and that any replacements on the inner dome were to be abandoned so that more repairs to the outer dome could be carried out.

The details on the lead sheet utilised on the outer dome were also specific to this building, but due to the use of square roll joints and work hardening when the bossing of the lead roll ends and intersections was carried out, many of the roll ends had failed. Due to financial limitations they have only been repaired.

J Hempstock & Co manufactured several hundreds of roll ends off site from templates. They were then welded into postion by operatives working via rope access over a period of several months.

J Hempstock & Co manufactured several hundreds of roll ends off site from templates. They were then welded into postion by operatives working via rope access over a period of several months.

Mike Hempstock explained the constraints put on the work by financial pressures: “Inherent issues with detailing and failure of the entire perimeter of 182 bays at the eaves were dealt with by adapting them to ensure that expansion is not restricted and the same failures do not re-occur. We were unable to carry out all the elements of work we recommended purely due to cost restraints and several areas have been left until they can be considered for repair at another time,” he said.

“The leadworks on both the Town Hall Extension and Central Library were just a small part of the entire transformation. Being involved has been a learning experience and working closely with teams from all parties has been done to the genuine benefit of the building and project.”

The works to the roof of this magnificent building were carried out over a period of 24 months and required great perseverance and skill – not least with the use of access equipment to ensure that the works were carried out safely and sympathetically while working within the strict programme allowances. It is very likely that, had the work not been carried out, several sections of the lead roof panels would have fallen away causing significant issues with their replacement and potential internal damage to the building.

Mike Hempstock summed up the experience: “The Manchester Town Hall Extension transformation project is nearing completion and we are privileged to have been involved. It will be a fantastic selling point for Manchester and is sure to become a brighter, more exciting place to visit – whether for studying or pleasure. I am certainly looking forward to spending time there with family and friends.”

• For more information visit www.hempstockplumbing.co.uk